13 Nov 2025

13 Nov 2025

Warehouse automation is changing how businesses manage operations, inventory and customer orders. For small and medium sized enterprises, it is a real opportunity to work smarter, cut costs and be more efficient. Yet many companies are still unable to connect automation investments to quantifiable business outcomes.

This article explores how SMEs can evaluate, implement and measure the return on investment (ROI) from warehouse automation. It decomposed the critical steps to recognise areas of improvements, establish specific performance measures and track results. It is aimed at assisting business executives to move past the generalised ideas and make specific actions yielding tangible operational and financial rewards.

Table of Contents

What Is Warehouse Automation

Warehouse automation involves the utilisation of tools such as robotics, conveyors, automated picking systems and software integration (ERP or WMS) that work together to reduce manual effort, errors and inefficiencies. It is not just about technology but it is about the payback of the technology. ROI is important since the investment must save costs, generate throughput gains or improvement in quality in a measurable manner. Research shows that warehouse automation can deliver payback in under 24 months and ROI exceeding 250%.

Learn more: The Difference between WMS and ERP System

Key Metrics to Monitor

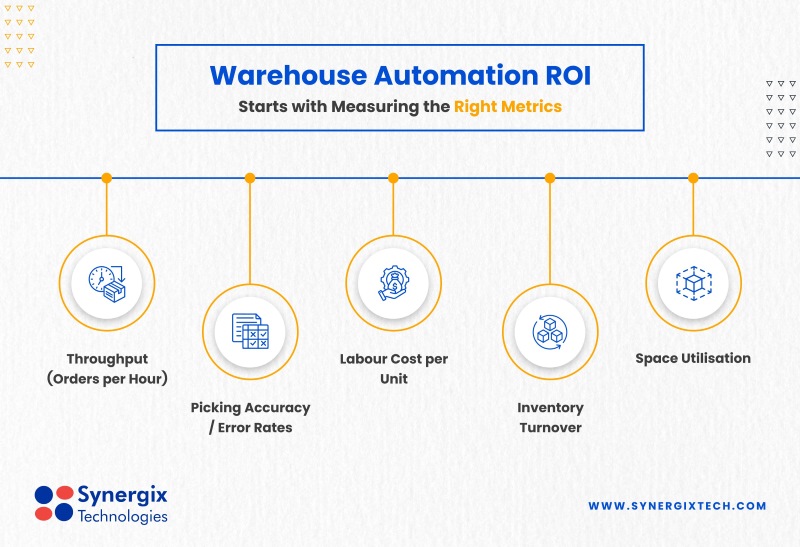

You must be aware where you are before you can invest, and where you would like to be. The following are some of the important metrics to measure as your yardstick:

- Throughput (orders per hour): Which number of orders does your team work with at the moment? What’s the realistic target?

- Picking accuracy / error rates: Mistakes are time, and money wastages. Monitor the rates of mistakes and their consequences.

- Labour cost per unit: Determine the cost of labour that is handled in every unit or order incurred. This should be minimised through automation.

- Inventory turnover: How fast does inventory move? When a company turns around quicker it is often more resourceful.

- Utilisation of space: How well do you use your warehouse space? Existence of bottlenecks or underutilised zones?

The value of measuring these provides a baseline to compare the performance of the process after automation and be able to calculate ROI.

Practical Steps SMEs Should Take for Warehouse Automation

Assess Current Processes

Understanding your current workflows is important. Visualise every view of the workflow, starting with goods delivery to shipment orders, and find the potential bottlenecks. Focus on manual repetitive processes which escalate labour expenses or make them prone to errors. This is the first review which lays the basis of a good automation plan.

Select Appropriate Scopes of Automation

Automation is not necessarily a zero-or-one choice. Other SMEs have begun with particular functions barcode scanning or automated picking and progressed to larger systems. The trick here is to adapt the project scope to your business size, budget and business priorities. A gradual or hybrid strategy would often give quicker and secure returns.

Choose Compatible Technology and Integrations

The technology you are appraising should integrate well with those that you already have in place. A successful automation project is based on integration. Synergix ERP system also integrates the activities of the warehouses with the top-down and bottom-up flows of the sales orders to the financial reconciliation and ensures that all operations are compatible among the different departments. This connexion will remove any duplication of data as well as reduce operational manual errors and increase cooperation among the warehouse, procurement and accounting departments.

ERP system being open system also accommodates third party integration like IoT sensors, conveyor, ASRS systems and so on to enable the SMEs to scale their operations whilst remaining efficient. Dependable vendor support, scalability, and well-established local service are also pertinent issues to promote the long term success.

Learn more: How ERP Make Impacts on Consolidation Warehouse Management

Develop Business Case and Secure Funding

An effective business case is one that incorporates a well-defined cost analysis and anticipated saving. Find the potential ROI by taking into consideration the less labour, fewer mistakes, and shortened fulfilment time. In Singapore companies may also consider local productivity grants, which will subsidise automation. This funding will bring digital transformation to more SMEs.

Pilot, Measure, and Scale

Start with a pilot project that will allow testing your assumptions. Gather information, analyse performance and make changes as necessary. Ensue measurements by use of dashboards and real-time analytics. When you start seeing the results, automate the process of every activity in the warehouse and keep producing similar results.

Common Pitfalls and How to Avoid Them

While warehouse automation brings clear benefits, certain pitfalls can reduce its effectiveness.

- Over-engineering: Select solutions which meet your needs instead of systems which are complex and not easy to maintain.

- Absence of change management: The staff should be trained and participate in the transition.

- Poor data quality: Automation requires a good data, clean and cheque up information prior to introducing it.

- Underestimating hidden costs: In any given budget, integration, maintenance, and upgrade costs should be included.

These problems are to be avoided to assist SMEs in the implementation process being smoother and return on investment faster. Synergix ERP solution has a good support in implementation and user training so that transition can be successfully made. The availability of a modular design enables the company to begin with few to serve as Inventory and Warehouse Management and gradually add other modules such as Finance or Sales. The gradual process also assists companies in realising profitability sooner and with minimal disturbance.

Fong Lee Metal Industries: Real Results with Synergix ERP

One of our clients, Fong Lee Metal Industries Pte Ltd, achieved remarkable improvements after implementing the Synergix ERP system.

In Fong Lee Metal Industries Pte Ltd’s testimonial, the company reported that order visibility became much clearer and faster, while searching and viewing records, such as purchase orders and quality reports, became effortless. Most notably, their Manufacturing Execution System (MES) was successfully integrated with Synergix ERP through an API, allowing smooth data sharing across departments.

Since adopting the system, employee productivity increased by 30%, supported by comprehensive training and responsive technical assistance from the Synergix team. The company also commended Synergix for its flexibility in integrating with other applications and tailoring functions to fit its operational needs.

This case demonstrates how an integrated ERP platform like Synergix can serve as the backbone of warehouse and process automation by linking people, data, and machines for measurable ROI.

Key Takeaways & Conclusion

- Measure what matters. ROI starts with the knowledge of what you are doing and what measurements you need to measure.

- Start small, scale smart. Automation of pilots in any category before rolling out through your warehouse.

- Integrate technology to business objectives. The optimal automation favours your workforce, operations and overall strategy.

Warehouse automation helps SMEs stay competitive, efficient, and ready for growth. It relies on proper objectives, proper data and proper implementation to succeed. Cheque out what you are already doing and see what you can improve and take measurements of what you do so that you can make future moves.

Synergix ERP facilitates the operations of SMEs to support end-to-end operations on a single platform. It can assist businesses to base decisions and scale too with real-time dashboards, mobile accessibility, and automation equipment compatibility.

Contact Synergix Technologies to have a free consultation and learn how your company can be faster, smarter and more profitably operated with better automation brought about by ERP.