28 Oct 2025

28 Oct 2025

In the case of small and medium-sized manufacturing companies in Singapore and Southeast Asia, inventory issues are immediately transformed into cash crisis. Stockouts delay production line and cancel sales, and surplus inventory clogs capital that could be used to develop the company. Failure to track work-in-progress (WIP) properly means that delivery dates will be missed as well as complaints by customers. The industry research indicates that ineffective inventory management costs the manufacturer 20-30% of inventory value each year in carrying and obsolescence costs as well as to effect rush orders.

This manual provides realistic approaches, ERP implementation models, and actual ROI statistics to ensure that SME manufacturers gain control over their inventories. You will have the time-tested techniques of minimising stockouts, maximising working capital and having systems that can grow and evolve with your business.

Table of Contents

- 1 What is Manufacturing Inventory Management? Key Concepts Explained

- 2 Why Manufacturers Are Losing Money Through Ineffective Inventory Management

- 3 Core Strategies & Practices for Manufacturing Inventory Management

- 4 Fixing manufacturing inventory pain points with an ERP (Such as Synergix).

- 5 How Synergix ERP system Fixes Manufacturing Inventory Pain Points

- 6 ERP Inventory Module versus Standalone Inventory Software

- 7 Conclusion

What is Manufacturing Inventory Management? Key Concepts Explained

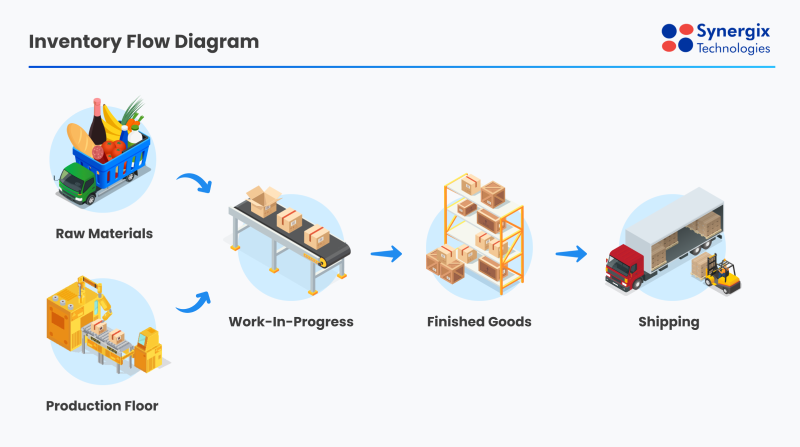

The system of control of raw materials, work-in-progress, and finished goods in the production cycle is known as manufacturing inventory management. In contrast to retail inventory, manufacturing inventory is changing raw materials forming WIP, further finished goods, where there is a strong necessity to track all the steps accurately.

Essential Inventory Types in Manufacturing

- Raw Materials: The components and materials bought by the suppliers until there is production. Example: sheets of steel, electronic components, packaging materials

- Work-in-Progress (WIP): It is items that are in production, and have used materials and labor but are not complete. Example: electronics that was partially assembled, the batches in chemical processing.

- Finished Goods: Finished products which are to be shipped to customers or distribution channels.

- Bill of Materials (BOM): A table showing the list of all raw materials, sub-assemblies, and quantities required to produce one unit of a final product. The basis of an accurate inventory planning is your BOM.

- Lead Time: This is the time it takes between ordering a purchase and having a useful inventory. Important in calculation of reorder point.

- Safety Stock: Buffer stock stored to ensure that there is no stockout due to a spike in demand or delays by suppliers.

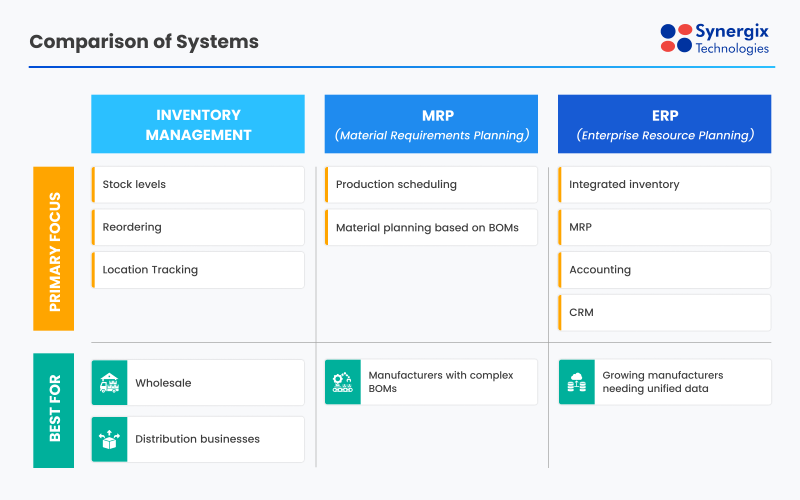

Quick Reference: Inventory Management vs MRP vs ERP

Why Manufacturers Are Losing Money Through Ineffective Inventory Management

There are six significant cost centers that are used to drain profits due to poor inventory practices:

- Carrying Costs (20-30% of inventory value annually): Rent of warehouse, insurance, handling labor, tied up capital. S$500,000 inventory costs S$100,000-150,000/per year to carry.

- Stockouts and Lost Sales: Each time production slows due to lack of materials, direct labor wages on wasted work hours are paid as well as possible lost customers who are unable to wait.

- Production Slack and Rush Express: Rush orders to plug shortages are usually 3-5 times higher than regular freight costs, killing margins.

- Obsolescence and Write-offs: This is particularly unpleasant in electronics and fashion manufacturing whereby over 12-18 months, components are becoming obsolete.

- Poor WIP Valuation: WIP is not an accurately-tracked account, so the financial reports wrongly report the businesses profitability, causing bad business decisions.

- Excess Cash Tied Up: Overstock indicates a working capital amount that can be used to purchase equipment, staff or to advertise are in a warehouse.

Critical KPIs to Track

Inventory Turnover Ratio = Cost of Goods Sold / Average Inventory Value

Example: A precision parts manufacturer with S$2.4M annual COGS and S$400K average inventory has a turnover of 6×/year (every 2 months). Industry benchmark for job-shop manufacturers: 4-8×.

Days Inventory Outstanding (DIO) = (Average Inventory / COGS) × 365

Example: (400,000 / 2,400,000) × 365 = 61 days. Lower is better—cash is tied up for 61 days on average.

Reorder Point Formula = (Average Daily Usage × Lead Time) + Safety Stock

Example: You use 50 units/day of a component, supplier lead time is 14 days, and you keep 200 units safety stock. Reorder point = (50 × 14) + 200 = 900 units. When inventory hits 900, trigger a purchase order.

Core Strategies & Practices for Manufacturing Inventory Management

Accurate BOM & Routing Management

Your DNA of manufacturing operation is your Bill of Materials. All the miscalculations in inventory can be linked to the BOM mistakes in wrong quantities, missing materials, or revision obsolescence.

Best Practices:

- BOMs that are revision controlled (revision control must never be compromised) and approved by engineers.

- Add waste/scrap variables (e.g. 5% scrap rate in cutting sheet metal)

- Connect BOMs with routing steps in such a way that at every work station, there are no material problems to consider.

- Periodic BOM audit: quarterly audit of 20% volume products.

Read more: Bill of Materials Management Made Easy with ERP

ERP Role: An adequate manufacturing ERP will have multi-level BOMs (sub-assemblies in assemblies), engineering changes with date effectivity, and automatically determine the needs of materials based on production orders. Spreadsheets are disaggregated at over 50-100 SKUs.

Inventory Visibility in Real Time

The practice of counting inventory every month or quarterly ensures that there is inaccuracy. The contemporary SMEs require real-time presence at several sites.

Implementation Steps:

- Barcode/QR system: Label all the raw materials bins, the WIP containers and the finished goods pallets. Either purchase handheld scanners (S$300-800 each) or smartphones with scanning applications.

- Serial/lot tracking: Traceability in electronics, medical devices, food production, is critical. Trace the lot of raw material that was taken into each batch of finished good.

- Multi-location sync: In this scenario you have a primary location and overflow warehouse or consignment stock at customer locations, you will have all locations updating the central system in real-time.

ERP Role: Scan issue materials to production orders to production orders and record production output and automatically deduct WIP as goods are completed. Dashboards indicate the stock location, lot, and status (in-QC, available, allocated).

Min/Max Inventory Rule of Automated Reordering

To ensure that the stockouts are prevented without unnecessary wastage of inventory, there is a need to manage the reorder points. The min/max method offers an easy, efficient mechanism to manufacturers in SMEs.

Setting Min/Max Levels:

- Minimum (Reorder Point): (Average Daily Usage Lead Time) + Safety Stock.

- Maximum: Economic order quantity + Minimum.

Assumptions: The mean stock is 50 units /day, lead time is 14 days, safety stock is 200 units, and order quantity is 1,000 units.

Minimum = 50 x 14 + 200 = 900 units (trigger reorder)

Maximum = 900 + 1,000 = 1,900 units

Setting Safety Stock: Simple formula: Safety Stock =(Max Daily Usage- Avg Daily Usage) x Lead Time.

IC: 50 units/day average, 75 units/day maximum, 14 days lead time. Safety stock = (75 – 50) x 14 = 350 units buffer.

ERP Role: Set min/max levels by item location combination. Below the minimum stock the system creates recommended purchase orders to be reviewed and approved with preferred supplier and lead time information pre-populated.

Best Practices of Cycle Counting and Physical Inventory

Annual wall-to-wall counts that close operations. Instead use perpetual cycle counting.

Cycle Counting Method:

- ABC Classification: Classify inventory based on value (A items = 20% of total value, counted every week; B items = 30% of total value, counted every month; C items = 50% of total value, counted every quarter)

- Daily count schedule: Count 20-30 per day. Warehouse 1-2, train 1-2: staff to be trained as dedicated counters.

- Variance exploration: Root cause analysis will be initiated prior to adjustment in case the variance is greater than 5%.

- Adjustment of the system: Immediate approval and reason code adjustment of ERP quantities.

- Target Accuracy: 95 percent + accuracy after 6 months of cycle counting program. Start with A items first.

Lean Pull Systems / Kanban for Repetitive Production

For manufacturers with repetitive production (same products daily/weekly), Kanban pull systems drastically simplify inventory management.

When to Use Kanban:

- High-volume, low-mix production

- Stable demand patterns

- Short production lead times (hours to few days)

Two-Bin Kanban Example:

- The workstation had two bins of Component X each containing 2 days supply.

- Upon emptying of the first bin, Kanban card is moved by the worker to replenishment board.

- Warehouse refill takes away bin and production takes second bin.

- Output: Visual inventory control is not computer transactions at workstation.

ERP Position: Kanban cards are scanned to issue automatic replenishment orders or production orders automatically, and keep the inventory at the best level without checkpoints of the reorders.

Lot & Expiry Control

Food, pharmaceutical, cosmetic and chemical producers that need a regulatory traceability requirement.

Implementation Requirements:

- Accept all lots/batches of materials with expiry date.

- FIFO (First In, First Out) enforcement: system will not release newer lots till older lots are used.

- Automatic expiry notices: 30-days notice of expiring items.

- Complete forward/backward traceability: supplier lot – production lot – shipment to customer.

ERP Role: Block issuance of out of date lots, produce recall reports that give all customers that have been provided with products manufactured under a particular raw material lot and also ensure that there is full audit trail to be used in regulatory checks.

Fixing manufacturing inventory pain points with an ERP (Such as Synergix).

The modern ERP systems designed specifically to address the needs of SME manufacturers overcome the inventory issues when equipped with real-time data management. These are the ways that particular characteristics will solve your pain points:

- BOM-Managed Production: Put together production orders that automatically allocate/reserve materials. Others Issue material, barcode scan, labor and machine time and receive finished goods, all coupled with costing.

- Multi-Location Sync: No matter whether you are operating out of a single facility or managing inventory in manufacturing, warehouse, and consignment locations, all the transactions are updated in the central location. Transfer orders are used to trace inter-location transfers on a full audit trail basis.

- Automated Reorder Workflows: Establish minimum/maximum levels at each item-location combination. System creates proposed purchase orders when stock quantities get below minimum with preferred supplier, lead time, and economic order quantity pre-populated.

- Supplier Lead Time Tracking: Tracking and recording actual supplier-item combination delivery times. System is a learner and provides best reorder points based on actual performance.

- Integrated Reporting: Relate inventory data to purchase, production and sales data to have in-depth analysis -inventory turnover by product category, sluggish inventory reports, material cost trend and more.

How Synergix ERP system Fixes Manufacturing Inventory Pain Points

Feature Mapping: Pain Point → ERP Solution → Expected KPI Improvement

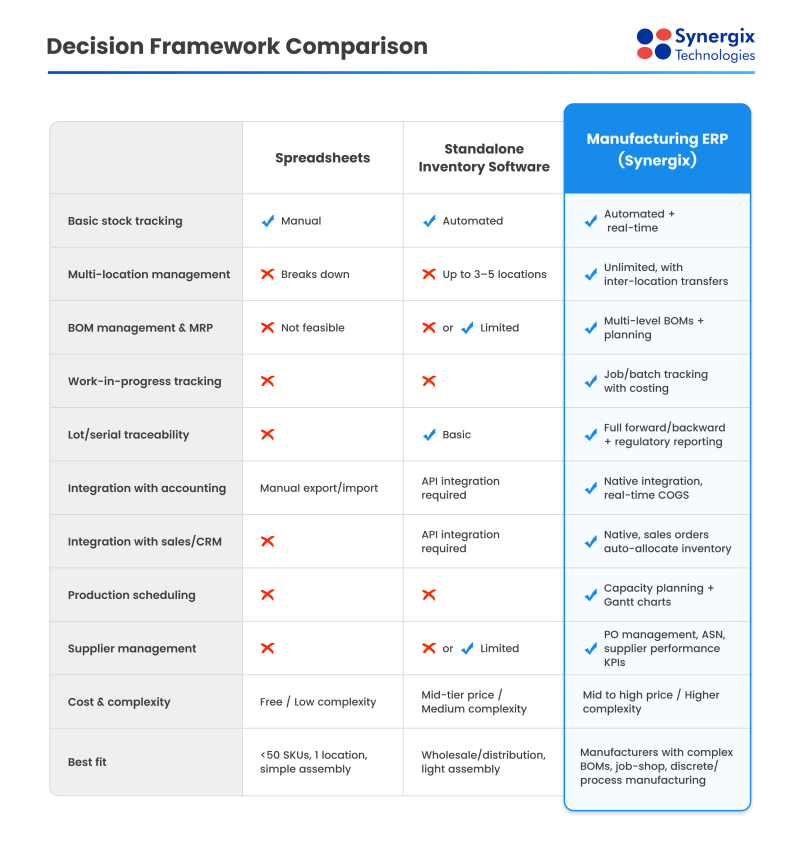

ERP Inventory Module versus Standalone Inventory Software

Not all manufacturers are ready to have a complete ERP at once. This is how to determine what is right at your business stage.

When To Use Standalone Inventory Software.

- You are mostly a wholesaler/ distributor with slight assembly/kitting.

- Single level BOMs with fewer than 5 components per finished product.

- None of the complex costing requirements (FIFO, standard cost, actual cost variance analysis).

- ERP Implementation planned in 2-3 years and require interim solution.

When it is time to select manufacturing ERP.

- Multi-level Bill of Materials (BOM) (sub-assemblies of assembly).

- Job-shop production or batch production which needs tracking of WIP.

- Need integrated costing: material overhead job or product.

- Several sites or intends to go bigger than present facility.

- Lot tracking (Regulatory traceability requirements) Audit trail (Regulatory traceability requirements).

- Inventory, accounting and quoting processes contain a lot of manual re-entry of data.

Conclusion

Inventory management is way more than easy counting stock, it is operational foundation that dictates how profitable you are, how satisfied your customers are, how you can grow. The issues SME manufacturers face, as we have discussed in this guide, are very real and expensive: they consist of stockouts, which stop the production, incorrect WIP valuation, which hides the actual profitability, manual processes, which waste valuable staff time, and inability to track materials through your supply chain.

Key Takeaways

- Profitability depends on how well the inventory is accurate: Cycle counting and ERP based tracking should be able to ensure that 95 percent or more precision can be achieved in 6 months. Lack of accuracy involves loss of 20-30% of inventory every year.

- Multi-level BOMs with version management help in eliminating the flaws and delays of using old version Excel spreadsheet. The basis of proper material planning is centralised, revision controlled BOMs.

- Real-time visibility is important: Firstly, it is better to know what you have, where it is, and what part of the production orders a firefighting decision-making is compared to proactive one.

- Min/max reorder automation removes half of the manual ordering labor and eliminates stockouts and excess inventory due to systematic replacement.

- Serial traceability and LOT. LOT is not an option in a manufacturing facility that encounters quality problems or government regulations. Extensive tracking of raw material to final goods is a safeguard to your reputation and can respond to recall very quickly.

- The tracking of the production process using all the work centers or the outsourced operations provide the production managers with the visibility to do the correct delivery commitment and identify bottlenecks.

- The methodology of implementation is more important than functions: a 90-day plan with executive sponsorship, super-users, and change management is a better implementation mechanism than a big-bang implementation.

- ROI is quantitative and quick: Effective manufacturing ERP systems normally pay back in 6-12 months due to decreased stock-outs, decreased carrying expenses and labour efficiency.