11 Dec 2025

11 Dec 2025

Production Management Software helps manufacturers plan, schedule, execute, and track work across the shop floor with greater clarity and control. The utilisation of spread sheets or manual updates is still common among many SMEs, and this introduces bottle necks and more chances of error. Co-ordination can be quite challenging because the teams operate with the information that is not centralised, and managers are unable to acquire a single picture of the production status. These problems bring down the productivity and competitiveness in an industry that considers speed and precision.

This article covers the main characteristics of the modern systems, the results they provide, and the criteria SMEs must take into account when choosing a solution. It also gives deployment options and provides a basic roadmap of implementation. Readers will gain a practical understanding of how Production Management Software brings structure, visibility, and measurable improvements to daily operations.

Table of Contents

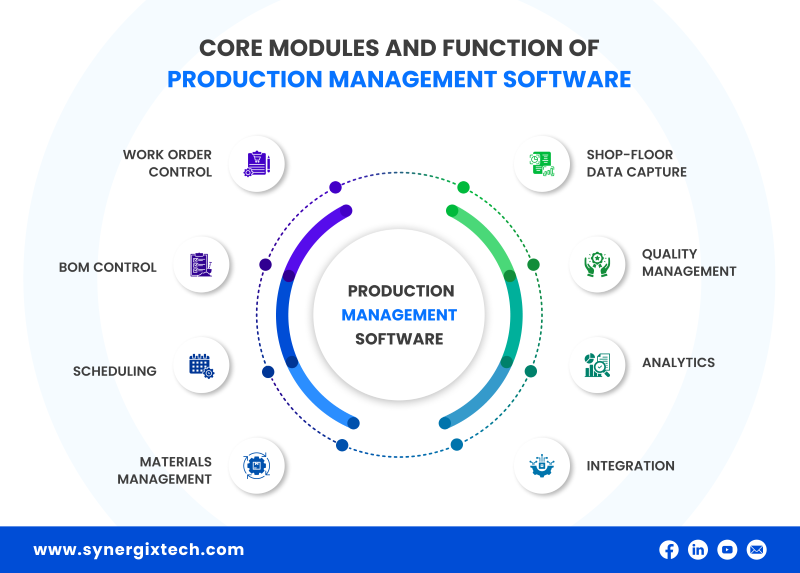

What Production Management Software Includes

An integrated system encompasses fundamental features that aid every production process. It normally starts with work order creation and routing in which the teams are aware of what they are to produce, the steps to take and the machines or work centres to use. The software handles Bills of Materials in version control such that when there are modifications in components or processes, they are always recorded. It also assists in capacity and finite scheduling where planned work is matched with available labour and equipment.

The other key area is materials management. The system verifies availability of materials, stocks and identifies shortages even before production commences. The operators record the data on the shop floor by using mobile devices, IoT, or barcode reading. Such information supports quality control gates and non-conformance oversight, which aids the identification of problems at a tender stage. Most of the systems also offer production analytics in the form of OEE, cycle time and yield.

Production Management Software often sits between an ERP and an MES. SMEs can begin with a specialised tool that manages work orders and shop-floor implementation. The system can be expanded to ERP modules of inventory, sale and finance. This will enable SMEs to grow at their comfortable rate without big initial investment.

Learn more: What Is Enterprise Resource Planning (ERP) Software?

Business Outcomes for Manufacturing SMEs

When used well, Production Management Software delivers results that matter to growing manufacturers. It enhances productivity since teams operate based on one, correct plan. Time and money are saved due to increased throughput and timely delivery of orders to customers. Practical research demonstrates apparent benefits. According to Bain’s Global Machinery and Equipment Report 2024, productivity can increase 30 to 50 percent with the help of accurate data and well-defined processes through the use of digital production tools.

There is also enhancement in quality because traceability gets improved. By having a greater insight into materials and work phases, companies minimise reworking and scrap. Real-time dashboards assist in making quicker decisions due to the ability of the supervisors to view delays, machine failure, or shortages of materials in real-time. Utilisation of labour and machines is enhanced due to schedules that are matched to capacity and not guesswork. The increase in inventory turns and reduction in lead times is the result of better coordination between planning and shop-floor execution.

These results assist SMEs in competing in their markets which require accuracy, speed and consistency. Production Management Software gives smaller firms the structure they need to scale with confidence.

Must-Have Features to Evaluate

Choosing the right Production Management Software starts with understanding which features make the biggest impact. The capabilities below enable SMEs in to handle the production in an accurate and confident way:

- Planning and scheduling: Finite capacity planning, clear constraints, and simple what-if scenarios to test alternatives.

- Work order control: Stage routing, live status updates and machine and labour booking.

- Materials coordination: BOM management, substitute items, backflush options, and alerts for shortages or reservations.

- Quality management: Activities of inspections, monitoring of non-conformance, CAPA and lot/serial traceability.

- Methods of data capture: Tablet access, barcode scanning, and IIoT connections of in-the-field machine data in real-time.

- Analytics: OEE, yield rates, cycle time, OTIF rates and cost-to-produce rates.

- Integration: API integration to ERP, finance, inventory, and maintenance.

- Usability: Role-based screens for planners, supervisors, and operators, with mobile access when practical.

- Security and audit: User permissions, approval workflows, and e-signatures where required.

The characteristics assist manufacturers in their accuracy and transparency in the production.

Explore: Synergix ERP Solution for Manufacturing Companies.

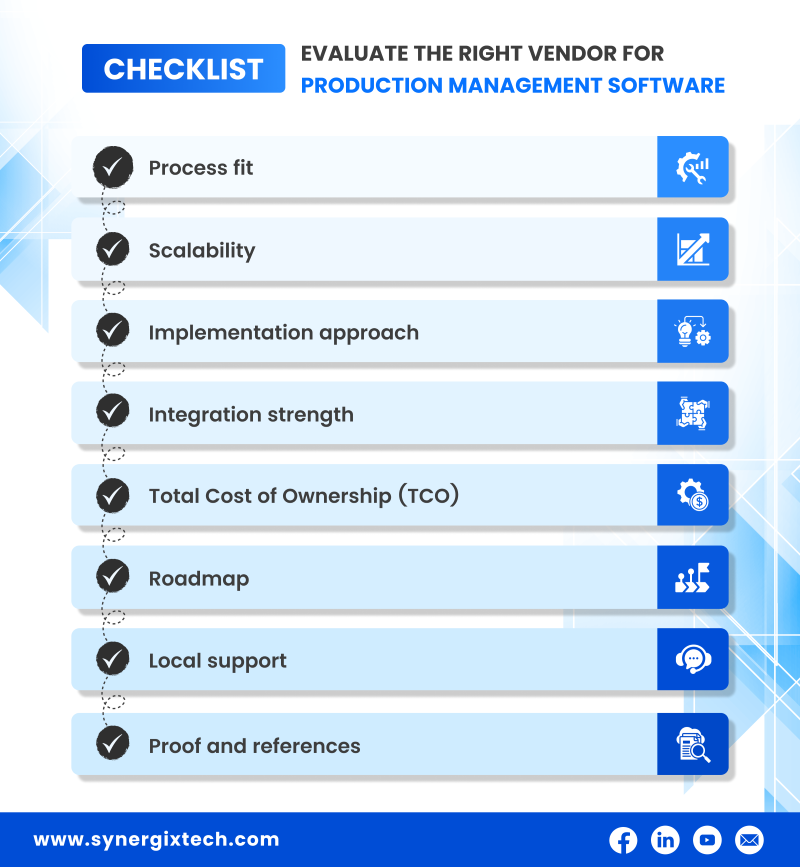

Choosing the Right Vendor: A Workable Checklist

Choosing a vendor for Production Management Software requires more than reviewing features. The system should be able to work with your type of production, either discrete, batch, or mixed mode. The high-mix low-volume manufacturers are advised to ensure that the tool can easily accommodate changeovers. Scalability is also an important factor particularly when a firm intends to add additional lines, increase the length of the shift or even to establish new locations.

Take into account the vendor implementation strategy. Some SMEs like the phased roll outs, meanwhile some use parallel runs. Superior training backup guarantees the teams to embrace the system fast. The depth of integration is also crucial, as the information about production is to move to ERP, finance, inventory, maintenance and QA easily.

Estimate total cost of ownership that consists of licences, devices, services, maintenance and upgrades. Audit the product roadmap of the vendor, the release cycle of the product, and the local support. Credible sources, pilot performance, and sample dashboard have valuable evidence prior to investing.

Learn More: Synergix ERP’s Production Management Module.

Client Testimonial: Tungray’s Experience with Synergix ERP

Tungray Singapore Pte Ltd noted that there have been vast changes following the adoption of Synergix ERP especially on the management of production and project data. Their team is now able to access historical BOM in a few seconds and this accelerates the planning of recurring or a similar job. The system also captures all project costs incurred in procurement through to fabrication and delivery, which provide managers with an accurate picture on profitability.

Dashboards consolidate updates on progress at each stage and enable leaders to make faster and more certain decisions. Tungray also made reference to the trustworthiness of the Synergix support staff who assisted in making it a seamless transition and further success. This experience confirms that the most suitable system can make a positive contribution to the control of production and increase the clarity of operations to manufacturers, who are heading to the direction of growth.

Key Takeaways

- Production management software gives SMEs clearer control and more predictable output.

- Real improvements come from clean data, consistent processes, and steady measurement.

- Small pilot projects reduce risk and help teams learn before scaling.

- Effective integration of planning, execution, and quality helps develop the long run resilience.

Conclusion and Next Steps

Production management software helps SMEs turn daily plans into reliable results. It enhances traceability, effective coordination and enhances quicker decisions throughout the shop floor. Those companies that gain the greatest are those which evaluate their operations fairly, operate a targeted pilot, and pursue profits in an organised manner. Each step brings clearer insight and smoother operations.

Should you have any questions on where to start, we suggest that you seek advice on a readiness review or a demo walkthrough of planning, execution and QA flows. Such meetings make you realise what can be done and what your company can become by using a modern system.

To sum it up, begin with one field, gauge progress and allow one advancement to result in another. For companies in need of an integrated system that provides connectivity between planning, production, inventory, and finance, Synergix ERP software is the ultimate solution to assist with automation and the long-term development. Contact Synergix Technologies now and arrange a free consultation to see how ERP will enhance your production management.